COCKPIT ......

09/24/2005 -- Here are a couple of photos of what has been done so far. Nothing

major has been constructed, but the main panel is done and the seat partially done. I

am using Eduard color photo etch for the cockpit as well as a cast resin ejection

seat. The seat will be dressed up with some tubing and wire to make it look more

realistic, and it will also get a coat of clear flat. It is still glossy right now

because I still have some work to do. The belts and harnesses are photo etch as well

and have not been added yet. Also note that nothing has been glued into the cockpit

yet. The panel and seat are just sitting in there for the photos which is why they

aren't sitting flush as they should. The panel sides fit into some slots in the

cockpit and will be flush when everything is done. Finally the tab on top

of the main panel is for the SAM warning gear. I'm not sure at this point whether

it will stay or not. I'm using parts from two resin sets and two PE sets on the

cockpit. It makes it kind of difficult to know what to use, what to ignore, what

to leave, and what to cut off.

There is an area above the red arm rest on the right side of the seat that looks like

red paint has gotten onto the gray frame of the seat. There are also some minor

areas around the yellow ejection handle that look the same way. Those are

reflections of the color on the gray seat frame. Everything is still glossy and

causing the reflections. It will go away when I get the seat flat coated.

10/17/2005 -- At the request of the owner I've made a couple of changes to the seat. The

tube along the edge of the seat has been revised so that it is right against the seat. The

garters have also been removed from the leg restraints. According to him they were kept

in their lockers with the other flight gear. When they got to the airplane they connected

the garters to the leg restraints. I also added a seat safety pin on the right side of the

seat with a "Remove Before Flight" streamer.

- The side panels are not glued in place. I will have to finalize the position of

them when the cockpit is installed in the fuselage, so right now they are just taped in

place.

- The ejection seat is not glued in place either. It will be permanently installed later and the leg restraints will be posed at that time. Right now they are just hung over the t-handles on the main panel and haven't been "Posed".

If I counted right, the cockpit consists of 118 pieces of styrene, resin, photoetch, foil, and

wire, so it did take some time to assemble. In addition to the

Legend Dimensions resin

ejection seat and parts of the

Eduard PE Seat the cockpit consists of the

Eduard Color PE Cockpit, the kit "Tub", and some wire and foil added for other details.

ENGINE ......

11/05/2005 -- One of the worst things about this model, and I remember it well from the

F-105G I built

last year, is the afterburner. The burner is a cylindrical section that is assembled

from four curved pieces. All four of the sections are liberally sprinkled with

ejection pin marks and other trash. To complicate matters even worse the four pieces

are ribbed so getting rid of the trash without ruining the ribs takes a good bit of

work. Once that is done you still have to assemble the four pieces and get rid of the

seams in the joints, not an easy task. I painted it once and wasn't happy with the

way it looked so I stripped it and repainted it. I'm still not completely happy

with the results but it's about as good as I can get it.

The remainder of the engine is pretty easy since virtually all of it will be invisible

once it is installed in the fuselage. The only things that really need to be

painted and detailed, other than the afterburner section, are the front and rear turbine

faces, the flame holder, and the exhaust nozzle. The engine is hollow and the front

turbine face is open but it will be visible through the intakes. I recommend that

you cut out a piece of sheet styrene, paint it flat black, and put it behind the front

turbine face to improve the appearance.

One other thing you can do that will help is to put a shield around the front face of

the engine. On both my F-105G and this model I constructed a cone-shaped piece

out of sheet styrene. It extends forward from the front of the engine to the rear

of the intakes. Anyone looking into the intakes won't be able to see the inside

of a plastic model that way and it looks much better.

Just for the record, when I look at a jet model one of the first things I do is look

into the intake(s) and exhaust(s) because, to me, these are the most difficult areas

of a jet to get right. They invariably contain lots of seams that are difficult

to remove, and making them look right makes the whole model look better.

AFTERMARKET RESIN ......

CUTTING EDGE CEC32154 FUSELAGE CORRECTION SET #1

This set contains, among other replacement parts, a repalcement ventral strake that goes

on the lower area of the fuselage, and it is a piece of cake to install. All that

is necessary is to cut off the old ventral strake and then slide the replacement resin

part into the slot that is left. When trimming the area of the fuselage for this

piece I'd recommend trimming it as smoothly as you can. The instructions say

to use a razor knife and score the existing strake tangent to the fuselage until it comes

off. This is probably the best and easiest way to do it, and only takes a couple of

minutes. It is important that the cut be smooth because the replacement strake is

thinner than the one on the kit. It fits the slot exactly but the cut edges of the

kit strake extend out past the resin strake and will be visible if they aren't cut smooth.

I notice in the photo that I still need to do a little sanding on that side of the strake

to. You can see a small line at the top of the strake (the bottom in the photo) where

the epoxy I used to glue it in place oozed out a little.

If you need a chuckle, take notice of what else the instructions recommend that you do

with the old strake! Since their instructions are copyrighted I won't include what

they said here, but if you want to know send me an

Email Message

All the white dust in the rivet holes and panel lines is sanding dust and will be

cleaned off thoroughly prior to painting. No point incleaning it off now since

I've still got some more sanding to do in places.

CUTTING EDGE CEC32150 CORRECTED FIN AND RUDDER

This is a complete replacement for the kit vertical stabilizer, engine cooling intake,

and rudder. The casting is excellent and aside from some minor dimples there were

no major flaws on mine that needed repairing. A couple of things I would recommend

though:

I also have concerns that adding these two big slabs of resin that far to the rear of

the main gear may move the center of gravity aft and make it a "Tail Sitter". Luckily

the Fuselage Correction Set #1 also includes a big resin radome that will offset a big

part of it. Additionally most of the centerline ordnance is in front of the main

gear, and since that is resin on this model that will help as well. The instructions,

Page 9, Section 16, incicate that 110 grams of weight (3.88 ounces) need to be added to the

nose. I added that, and have a big, heavy resin radome that I added a 1/2 ounce of

lead to so everything should be fine. I won't know for certain until I get everything

assembled and the model sitting on all three legs. There is some room left in the

nose for more weight, so it isn't a major problem as long as the radome is left until the end.

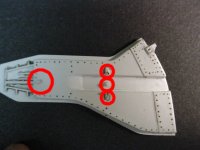

BLACK BOX WHEEL WELL UPDATE SET

While quite well molded and detailed the instructions for this set are absolutely

dismal. I got most of them done today (which took about 7 hours) and the best

advice I can offer is to work on one side at a time, use the other side for reference,

and be certain of what you are doing before you cut something. It would be very

easy to use a part on the wrong side or cut the wrong thing off because you cannot tell

ANYTHING from the instructions. The parts fit isn't bad, not great but not bad,

and the detail is much better than the kit parts. It is worth the effort but you

have to pay close attention to what you are doing.

Note that I installed all of the parts on the upper wing half whereas the kit had part of

them on the lower half. Since they have to fit together it's just a lot easier to

install them on the top half.

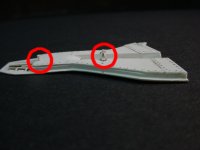

I still have some cleanup to do, you can see a slight gap between the wheel bay and the

bay wall that I need to fix, and perhaps some sanding when I get around to actually

fitting the wing halves together. I don't want to do too much until I get ready to

glue the wing halves together because I want them to touch the other wing half. I

also wanted to photograph the installation just as the parts go together. You may

notice some short sections of white styrene on the left side of the bay wall. There

are two molded wires there that prevented the wall from fitting properly because they

curved down and then back up right where the crossmember fits against the main section

of the bay. I sanded them off and replaced them with some short sections of

styrene rod of the same diameter.

There is also an obscure note on the instructions about cutting a 35mm slot on the intake

that is molded on the fuselage. This is because the wheel wells are larger than the

kit wheel wells, and also because while Trumpeter molded some of the wiring and the auxiliary

intakes on the sides of the fuselage while Black Box molded them into the wheel well. Be

aware that if you do cut this slot then the edges of the wheel wells will be visible to

anyone who looks down into the intakes. I spent a good bit of time grinding and sanding

both the wheel wells and the fuselage and did manage to get everything to fit without having

to slot the sides of the fuselage. I may have a minor seam to deal with where the bottom

of the wing joins the fuselage but to me this is preferable to having the wheel wells visible

through the intake. That would just be wrong.

The "Lateral Walls" as BlackBox calls them, the "U" shaped piece going to the lower right

in the photo above where the main gear struts would fold into, are VERY difficult to work

with. Someone at BlackBox thought it would be a good idea to mold both of them on

the same piece of resin, sort of interlocked together. Cutting them out without

breaking them is ROUGH (ask me how I know!), and once they are cut out the excess resin

has to be sanded off the bottoms without breaking them. I'd also recommend that you

temporarily put the two wing halves together and use a Sharpie to mark right against the

inside of the kit walls so that you will know how to line up the resin pieces.

When I started to fit the wing halves together to determine how much to grind off of the

fuselage to get everything to fit I also noticed that the height of the "Lateral Walls" did

not match the height of the inside of the wing. I wound up having to glue some

pieces of styrene sheet to the top of them (they are located on the lower left section of

the lateral wall in the photo above, but are not shown in the photo) and then sand it to

the proper height to eliminate the gap between the lateral wall and the bottom wing half.

Also notice in the photo above that the top of the "Lateral Wall" just sort of stops. It

doesn't connect to anything at all. After looking at some photos I decided that was

just wrong so I used a small piece of sheet styrene to close the area off.

The nose gear well isn't molded quite as cleanly and there was a good bit of overcast

among the tubes and hoses and wires that I had to clean off. It didn't take a lot

of work but did need some cleanup.

The gear doors included in the set are more detailed than the kit doors. The molding,

however, is not very clean in some places and somewhat difficult to clean up. Some

of them are also quite difficult to separate from the casting blocks so be careful and

take your time with them.

All in all this conversion set is a lot of trouble to install but if one takes their time

and is careful with their work it makes for a much more realistic model. Is it

worth the effort to install something that will seldom, if ever, be seen? I can't

answer that question for everyone, but it was for me.

Here is a photo of the installed ventral strake. The image to the left is a link to

a larger image. Click that thumbnail to view the larger photo. Notice that I

added a small piece of styrene on the aft and sanded it to match the profile of the

strake. The end of the ventral strake should be very close to the frame that holds

the arresting hook.

The kit also includes a replacement radome and RHAW antenna / strike camera. If

you follow the instructions the pieces go together quite well. You have to sand the

nose of the fuselage down about 1/8" (down to the first panel line).

Here is a photo of the cut-down fuselage. The image to the left is a link to

a larger image. Click that thumbnail to view the larger photo. Notice that

after sanding you are left with three small notches that would hold the latches of the

factory nose cone. I used some 0.040 styrene to fill them in, and if you look closely

in the photo you can see that I let them extend inside slightly. The resin radome

fits slightly loose so I used these three pieces to tighten up the fit. It won't

matter at all once the radome is glued in place, but for fitting pieces I prefer to have

things fit somewhat tight. The radome is not glued in place at this time, it is only

stuck in the fuselage opening for the photograph.

The instructions have a note to add 100 grams (3.88 ounces) of weight in the nose. Since

the resin radome was solid it just seemed appropriate to drill a hole in the rear of it

and epoxy a 1/2" lead weight into it. I didn't try to get it all the way into the

radome, I just ground out a cone-snaped hole, stuffed it full of epoxy, and stuck the

weight in. I'll still need to add some more but since this was so far forward it

just made sense to add some weight there as well.

Here is the resin radome installed in the fuselage. It is not glued into place, just

stuck in the fuselage for the photograph. As can be seen it fits quite well.

The factory RHAW antenna / strike camera underneath the nose needs to be cut off. It

also needs to be cut off in such a way as to leave as much of the underlying plastic as

possible since the resin replacement isn't as wide as the factory one. I cut this

one off with a razor saw slightly above where it neets with the fuselage and then sanded

it down smooth. This leaves the thickness of the plastic in place. The inside

of the cut doesn't have to be smooth. Cutting Edge gives you a choice of an RHAW

antenna alone, a combination RHAW antena / strike camera, or neither. If you choose

the "Neither" option they include a resin plug to close up the hole that is left.

Here is the resin radome and combination RHAW antenna / strike camera balanced in

place. The parts are not glued in place which is why there is a big huge gap between

the radome and fuselage.

Here is a photo of the inside of the top half of the right wing showing the installation

of the pieces. The image to the left is a link to a larger image. Click that

thumbnail to view the large photo.

Here is a photo of the inside of the top half of the right wing showing the installation

of the pieces. The image to the left is a link to a larger image. Click that

thumbnail to view the large photo.

|

|

|

Notice in the photo to the left that both the main gear doors and the Scale Aircraft Conversions metal main gear

BOTH have the brackets that mount the gear door to the gear strut. One of the two has to go because they

both can't occupy the same space! I chose to sand them off of the gear doors and use the ones cast onto the

gear struts since that would provide a more secure mount for the doors. Note that this may not be a problem

with either the kit gear struts or another brand of metal gear, but it is a problem with the ones I used.

While you are sanding, you might as well remove the pins that locate the door onto the gear since they don't line

up properly either. The one toward the bottom of the door won't even reach the gear unless you cut the brackets

off of the gear strut and use those molded on the gear door. The one to the top is about 1/32" off of where

it needs to be for the doors to line up properly. Again, let me emphasize that this may only be an issue with

the Scale Aircraft Conversions metal main gear. I really like that cast metal gear and highly recommend it,

however it doesn't mate well with the BlackBox main gear doors.

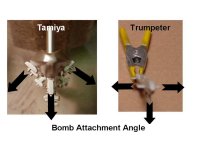

CUTTING EDGE CEC32014 M117 750lb BOMBS

This resin set provides a complete replacement for the M-117 bombs in the kit. When used in conjunction with the Eduard 32208 F-105 Thunderchief Armament Set the result is some highly detailed replicas of the M-117 750 pound general purpose bomb.

|

The set contains four complete bombs in the package, and each bomb consists of seven pieces as shown in the photo to the left. A nose section, a tail section, four fins, and your choice of a nose fuse or nose plug. Note that the casting plug has been cut from the nose and tail sections for this photograph. They are not difficult to cut off, just put a razor saw right against the shoulder where the plug joins the part, saw a little bit, rotate the part, saw a little more, and repeat. Keep the saw right against the shoulder and the parts will cut rather cleanly. |

|

The only problem I ran into assembling them was that the nose section of most of the bombs was not cast square. As can be seen in the photograph the 90° triangle does not line up with the edge of the bomb. It isn't a real serious problem, it just takes a little sanding to correct. At first I thought it was the way in which I was cutting them from the casting plug, but when nearly all of them were the same way and the tail sections weren't I decided it wasn't me. |

|

Here is one that is roughly primed. I wanted to see how much of a gap I had to fix between the fin and the tail, and judging from this photo I still need to do some work on it. Also notice that the gap between the front section and tail section is completely gone. The real ones show a panel line there as can be seen on This Photo Of The Real Thing on GlobalSecurity.Com's web site (an excellent resource for ordnance photos, by the way!) so I will probably go back and scribe a panel line on them. I prefer to do that than try to maintain an even panel line depth when gluing parts together at the panel line. |

|

I didn't like the way the decals fit the bombs so I decided to paint the yellow nose stripe. Masking around a curve

such as the nose of a bomb is not the easeiest thing in the world to do but with a little time and effort it can be

done. The photo to the left shows one bomb masked (top of the photo) and a second with an initial coat of light

gray primer. I have never found yellow paint that covers very well so if the base color is dark I always spray a

coat of something light in color before the yellow.

To mask them two pieces of tape are needed, and they need to be cut on an arc. For these particular bombs the piece to the rear was cut on an arc with a 0.740" diameter and the one at the front was cut with a 0.520" radius. The stripe is 3/32" in width, the masking tape at the rear is 5/32" from the nose and the piece at the front is 1/16" from the nose. |

Here's a hint for sanding the halves: Place a piece of sandpaper on a hard surface (I like to use flat ceramic tiles), then sand the part in a figure-8 motion across the sanepaper. If you do this you won't get a rounded or off-center end, it will be nice and smooth and even. Unfortunately the photo of the nose section in the middle photo above doesn't show that very well. If you look where it is sitting on the ceramic tile you can see a slight gap on the left side and it should be completely flat on the surface. I haven't assembled that one yet so I need to work on it a bit more. However, as can be seen in the photo of the assembled bomb above it is so even that when the parts are glued together there is hardly any gap at all. I used 2-part epoxy to glued the halves together, by the way. Once it cures it sands quite easily and conforms very well to the shape of the bomb.

GENERAL ASSEMBLY ......

LEADING EDGE FLAPS

The leading edge flaps are somewhat problematic. Specifically, they fit really

badly. You can see what I mean in

This Photo of the F-105G I built last year. Keep in mind that the photo was

taken after messing around with them for a good while getting them to fit that well.

I've decided to change tactics on this "D" model. The parts are the same as on my

"G", but this time I chose to leave out all of the hinges and pins that Trumpeter

provides because they cause a good bit of the fit problem. The flaps are designed

to pivot, but I wound up gluing them closed on my "G" and this one will be built with

them closed as well. I also closed off the back of the assmblies with a piece of

0.020" styrene sheet 5 5/16" long x 3/16" wide at the inboard end and 1/16" wide at the

outboard end. The flaps are hollow but there is a ledge inside the back that the

strip of styrene fits into quite well. I used a styrene pin in the middle of the

rear of the flap (a piece of 0.025" styrene rod) drilled through the backing and into

the leading edge of the wing to hold things in place and then glued it using Tenax

7R. I still had to do some sanding and then escribe the line between the flap

and wing, but all in all it worked much better than on my "G" model. A couple of

photos are included below, but I still need to do a little cleanup on the

joint. As can be seen in the photos there is a bit of a gap on the bottom side

of the wing but there may actually be one like that on the real thing.

The five small spoilers at the rear of the wing

look like they are sticking up in the photo but they are not, they are dead flat with

the surface of the wing. I'm going to have to go back and rescribe the panel lines

between them and the wing because the sanding completely eliminated most of them.

INTAKES

I could probably have left the seam there since there is a track for the intake plug

that runs right down the centerline of the intake, but I would have known it was a seam

and I plan to do something different for the intake plug track.

The intakes have an evil seam on the inside where the two wing halves join. It

is about 1/16" wide and pretty deep, and even Tenax 7R glue didn't help very much. A

little bit of putty using

Matt Swann's "Fence" Method

followed by some sandpaper wrapped around around a wooden dowel makes pretty short work

of them though. As can be seen in the photo, all that is left of the seam is a

reflection and some white putty that will disappear when it is primed. Just be

sure to take care of it before installing the wing on the fuselage, it is a LOT harder

to fix then (I made that mistake on my "G" last year!).

The intakes have an evil seam on the inside where the two wing halves join. It

is about 1/16" wide and pretty deep, and even Tenax 7R glue didn't help very much. A

little bit of putty using

Matt Swann's "Fence" Method

followed by some sandpaper wrapped around around a wooden dowel makes pretty short work

of them though. As can be seen in the photo, all that is left of the seam is a

reflection and some white putty that will disappear when it is primed. Just be

sure to take care of it before installing the wing on the fuselage, it is a LOT harder

to fix then (I made that mistake on my "G" last year!).

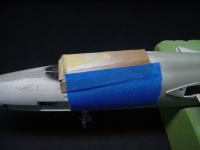

COCKPIT PROTECTION

On this particular model the nosegear is also easily damaged since it has to be installed

before the fuselage is closed up. I have a similar cover for the nosegear but it was

off when the photo was taken. This nosegear is metal so it won't break easily but

the paint is aluminum metalizer and is somewhat fragile.

Once the fuselage is assembled the cockpit presents a rather delicate assembly that

is just looking for a chance to get broken. This is the method I use to protect

them during assembly. I cut a piece of stiff cardboard and bend it to fit over

the cockpit area and tape it in place. It's quick and simple and goes a long way

to help prevent damage to your cockpit.

Once the fuselage is assembled the cockpit presents a rather delicate assembly that

is just looking for a chance to get broken. This is the method I use to protect

them during assembly. I cut a piece of stiff cardboard and bend it to fit over

the cockpit area and tape it in place. It's quick and simple and goes a long way

to help prevent damage to your cockpit.

LANDING GEAR

This is a large and heavy model when completed, and I don't think that the plastic landing gear provided in the kit

is strong enough to hold it up. It might last for a while but I suspect that over time they will begin to

bow. To be honest though I never even tried them. I used metal gear for the

F-105G I built in 2004 as well as this one. If anyone has built this model and used the plastic gear I would

be interested to know how well it has held up, and will be glad to add your comments to this page.

Personally I strongly recommend that anyone building this model invest in a set of cast metal landing gear, it is

well worth it. There are two companies I know of that provide these parts:

Scale Aircraft Conversions (available from Meteor Productions) and

Aeroclub Models. The Scale Aircraft Conversions set

contains the main gear only whereas the Aeroclub Models set includes all three gear struts. There may be other companies

that provide these parts but these are the only two that I am aware of.

WEIGHT AND BALANCE

This model will be a tail-sitter if you don't pay attention to what is going on! The instructions, Page 9, Section 16,

incicate that 110 grams of weight (3.88 ounces) need to be added to the nose. With all of the resin I added to the

rear of this model I added about 6 ounces of lead to the nose to be safe. From everything I can tell so far it will

be fine, but I'm leaving the nose cone off until the very end so that I can epoxy some more lead in the nose if I need to.

This additional weight also emphasizes the need for stronger landing gear, especially the main gear. See the

paragraph above pertaining to the landing gear.